Are you currently in the process of selecting window frames for your home? This daunting task can come with many important choices to make. You’ll run across two popular frame options: extruded window frames and roll-form window frames. What are they, and which is right for you? Read on to learn the pros and cons of each to help you make an informed decision about which is the best choice for your home.

Roll Form Window Frame

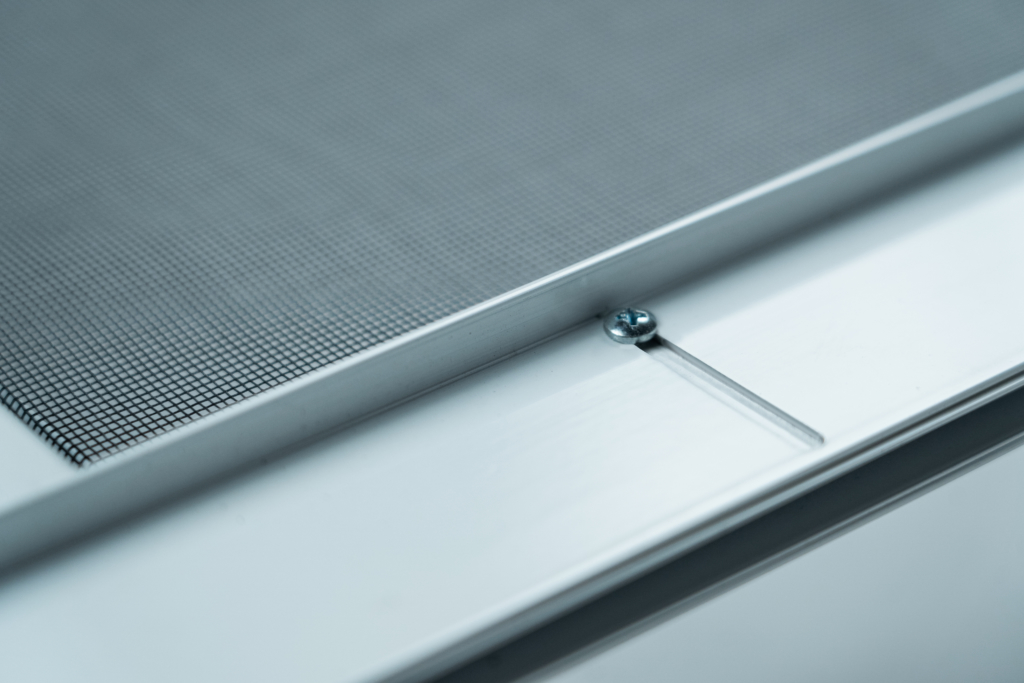

A roll form window frame refers to a type of window frame manufacturing process. In this method, flat metal strips (usually aluminum or steel) are passed through a series of rollers that gradually shape and form them into the desired window frame profile. The rolling process creates a continuous, seamless frame without the need for additional welding or joining.

Pros

- Cost-effective: Roll form window frames are often more budget-friendly compared to other construction methods, making them an attractive option for cost-conscious homeowners.

- Lightweight: These frames are lightweight yet durable, providing a sturdy structure without adding excessive weight to the window system.

- Seamless appearance: The continuous rolling process creates a seamless frame without visible joints or welds, resulting in a sleek and aesthetically pleasing look.

- Ease of installation: The lightweight nature of roll form frames makes them easier to handle and install, simplifying the installation process for homeowners or contractors.

Cons

- Limited material options: Roll form window frames are typically made of metal, such as aluminum or steel because of the manufacturing process. If you have a specific preference for alternative materials like wood or fiberglass, roll form frames may not fulfill your aesthetic requirements.

- Less design flexibility: While roll form frames can be customized to fit various window sizes and styles, they may have certain design limitations compared to alternative construction methods.

- Thermal conductivity: Roll form frames made of metal can have higher thermal conductivity compared to materials with better insulating properties, such as wood or vinyl. This may result in slightly lower energy efficiency and potentially contribute to heat loss or gain in your home.

- Potential for Condensation: Metal frames, including roll form frames, can be more prone to condensation in certain climates or humid environments. Adequate insulation and proper sealing measures should be in place to prevent this issue.

- Maintenance Considerations: While roll form frames are generally low maintenance, they may require periodic cleaning and care to prevent debris buildup and ensure optimal performance. Plus, metal frames are more susceptible to corrosion or rust in certain conditions, requiring regular inspection and maintenance.

- Weight limitations: Due to their lightweight nature, roll form frames may have weight limitations when it comes to supporting heavier glazing options or accommodating specific structural requirements. It’s important to consider the intended use and compatibility with your desired window configuration.

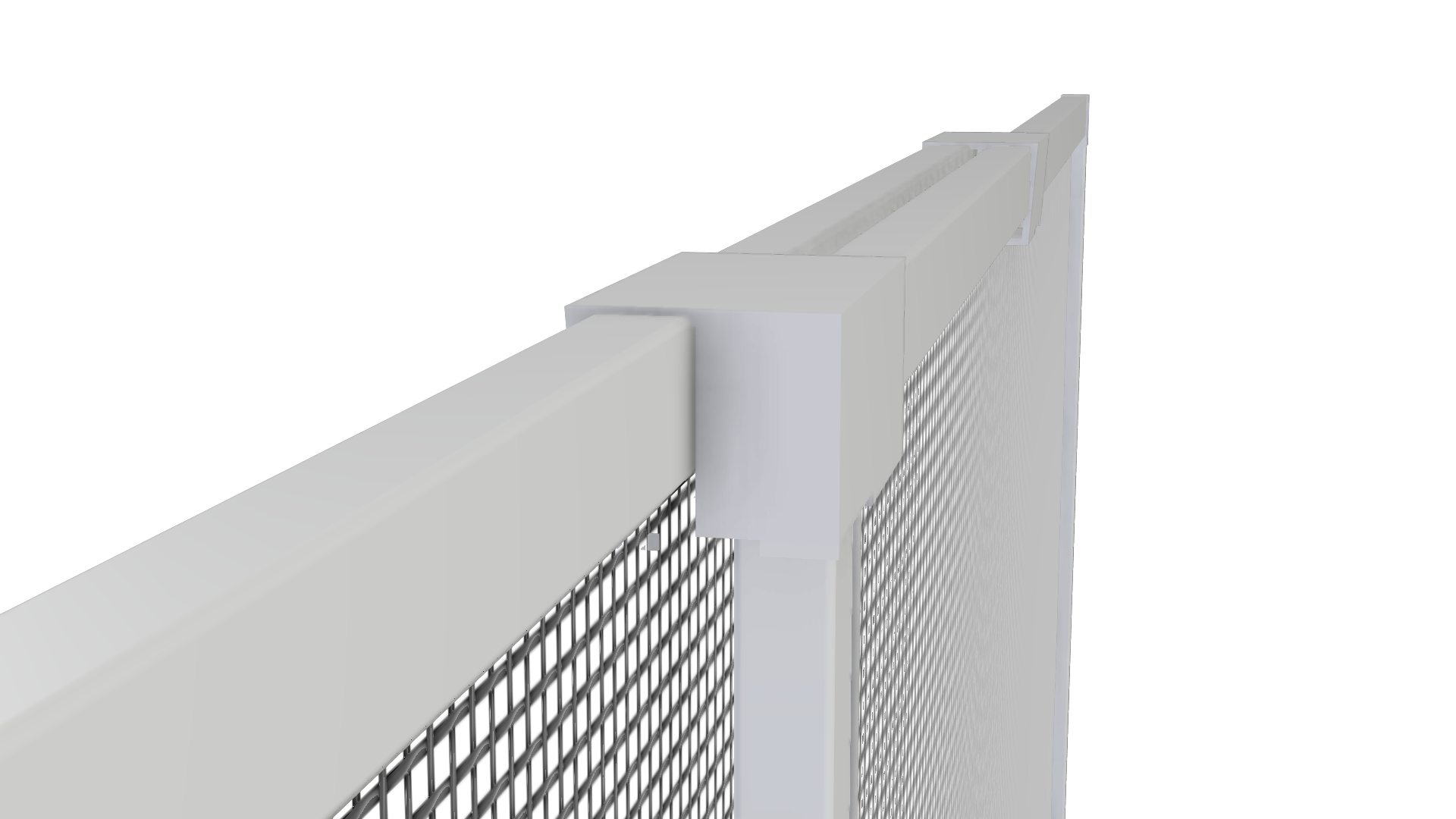

Extruded Window Frames

Extruded window frames are a type of window frame construction method widely used in the industry. They are created by forcing heated aluminum or vinyl materials through a specialized machine called an extruder, which molds them into the desired shape. This process results in window frames with consistent dimensions and excellent structural integrity.

Pros

- Durability: Extruded window frames are known for their exceptional strength and durability. They are highly resistant to warping, bending, and cracking, ensuring long-lasting performance even in challenging weather conditions.

- Structural Integrity: The extrusion process results in window frames with consistent dimensions and solid construction. This provides excellent structural integrity, contributing to the overall stability and security of your windows. They can withstand the test of time, reducing the need for frequent replacements, which saves you money in the long run

- Energy Efficiency: Extruded frames often have good insulation properties, reducing heat transfer and helping to maintain a comfortable indoor environment. They can contribute to improved energy efficiency, potentially lowering heating and cooling costs over time.

- Low Maintenance: Extruded window frames typically require minimal maintenance. They are resistant to moisture, pests, and decay, eliminating the need for frequent repairs or repainting. This makes them a convenient and time-saving choice for homeowners.

- Noise Reduction: Extruded window frames (especially those with proper sealing and glazing) can help minimize external noise infiltration for a more peaceful indoor environment.

Cons

- Cost: Compared to other window frame options, extruded frames can be relatively more expensive. The initial setup and tooling required for the extrusion process contribute to higher manufacturing costs.

- Design Limitations: Although extruded window frames can be customized to fit various window styles, they may have certain design limitations compared to other materials like wood or fiberglass.

Choose Longevity. Choose RiteScreen for your Extruded Window Frame.

At RiteFit by RiteScreen, we pride ourselves on providing our customers with the most durable, long-lasting window frames. We offer extruded window frames to ensure we are giving you the best product. Not only is RiteFit the easy choice from our GenExt extruded window screens to our Fully Assembled, Pre-Framed options. And with new Multi-Fit screen’s proprietary frame technology, you only need to know your window frame measurement to the nearest whole number, making it easier than ever to order the screen you need. The product ships assembled, does not require on-site alterations, and is ready for you to install yourself in just five minutes!

Head to the RiteScreen store on Amazon and have your new window screen delivered with Prime Shipping to start your DIY extruded window screen replacement project!